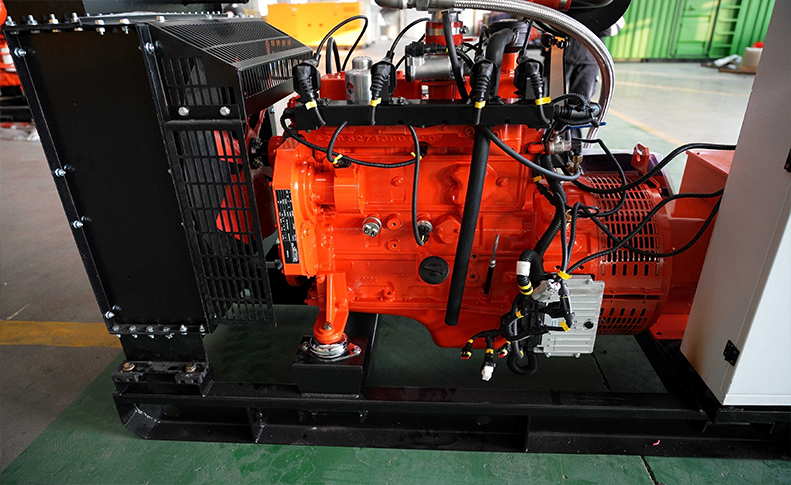

Integrated Generator Set Design

The generator set adopts a compact skid-mounted configuration that integrates the gas engine, alternator, cooling system, LPG supply system, and control panel into a single, well-organized unit. This integrated design simplifies transportation, reduces installation complexity, and allows for fast commissioning on site. The compact footprint makes it suitable for locations with limited space, both indoors and outdoors.

Cummins LPG Gas Engine

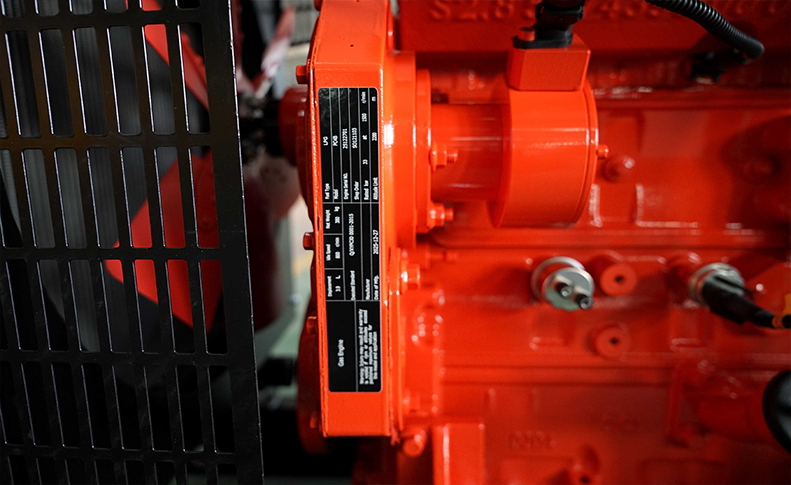

At the core of the generator set is a Cummins gas engine specifically configured for LPG operation. The engine features optimized combustion geometry and a dedicated gas fuel system that ensures smooth ignition and stable combustion. It maintains reliable performance under varying loads and operating conditions, providing strong load acceptance and steady output throughout extended running periods.

Reinforced engine components and precision manufacturing ensure durability and long service life. The engine design supports continuous operation while maintaining stable operating temperatures and controlled vibration levels.

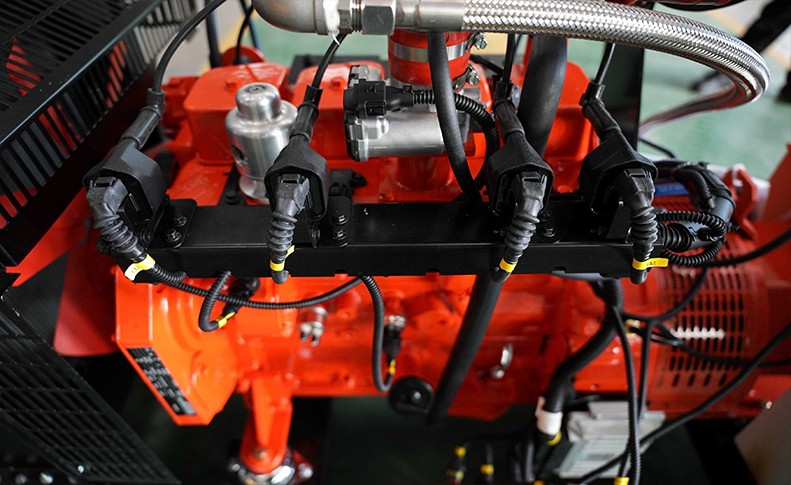

LPG Fuel Supply and Safety System

The LPG supply system is designed with a strong emphasis on safety and operational stability. High-quality valves, regulators, piping, and fittings ensure accurate gas flow control and a stable air–fuel mixture. The system is engineered to minimize leakage risks and maintain consistent combustion performance under different load demands.

This optimized fuel system improves fuel utilization efficiency, reduces combustion fluctuation, and contributes to smoother engine operation and longer maintenance intervals.

Cooling and Thermal Management

An efficient cooling system is incorporated to maintain optimal engine operating temperatures. The radiator and airflow design ensure effective heat dissipation, even during long-hour operation. Stable thermal management helps protect critical engine components and supports reliable continuous performance.

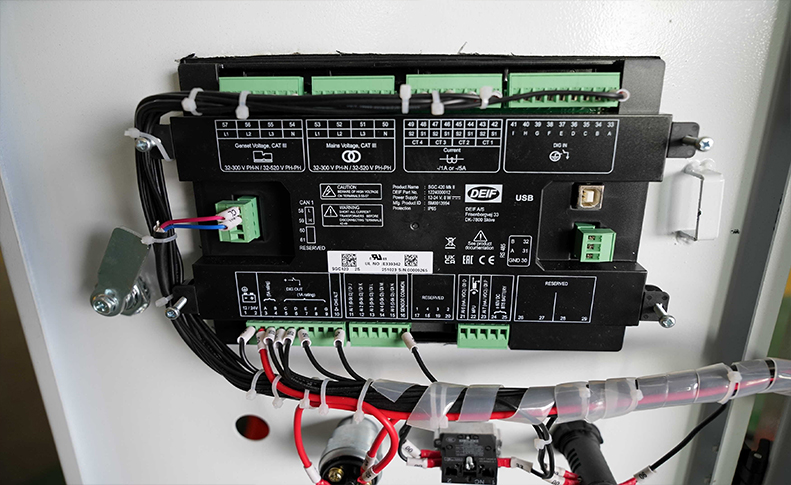

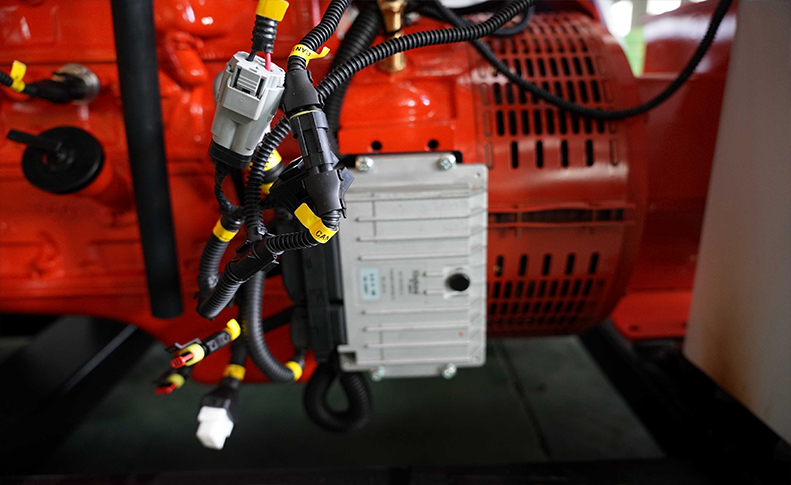

Electrical System and Control Panel

The generator set is equipped with an intelligent control panel that provides automatic start and stop, real-time operating data display, alarm protection, and fault shutdown functions. Key parameters such as voltage, frequency, power output, and engine status are clearly displayed, allowing operators to monitor system performance easily.

The internal control system uses well-organized wiring and high-quality electrical components. Clear layout and reliable connections improve system stability and simplify troubleshooting during operation and maintenance.

Maintenance-Friendly Structure

The generator set is designed with ease of maintenance in mind. Key service points such as ignition components, filters, gas system parts, and sensors are easily accessible. This reduces service time, minimizes downtime, and lowers long-term operating costs for the end user.

Quality Control and Factory Testing

Each Cummins 30 kW LPG generator set is manufactured under strict quality control procedures. Before shipment, the unit undergoes comprehensive factory testing, including engine operation checks, electrical output verification, and system safety inspection. This ensures that the generator set is fully operational and ready for immediate installation and commissioning on site.

Applications and Benefits

With low fuel consumption, clean emissions, and reliable performance, the Cummins 30 kW LPG generator set offers an excellent alternative to diesel generators. It helps users reduce fuel costs, lower environmental impact, and achieve stable power supply in a wide range of applications, including residential backup systems, commercial facilities, farms, workshops, and small industrial sites.